10 business processes that can be automated with Orderwise integration

Integration is more than just a data connection

ERP integration is often seen as a background IT task, just syncing data between systems. In practice, it’s a smart, strategic move that helps you automate processes, scale operations, and create real growth opportunities.

This article doesn’t look at the foundations of a sucessful ERP integration; we cover that in our guide on what a reliable ERP integration looks like.

Instead, it’s a practical look at what you can automate when your Orderwise integration is working as it should. We’re focusing on the business-wide processes that save time, reduce costs, and cut out admin.

Many businesses look at integration to improve their eCommerce site and the customer experience. That matters. But the biggest operational gains come from the back end, where time is saved, errors are avoided, and processes scale cleanly.

Orderwise is a capable ERP. It handles complex inventory, purchasing, dispatch, and financial workflows. Its value grows when the data and logic inside it drive faster, smarter internal processes.

This article covers 10 real-world business processes you can automate through Orderwise. If your teams are still double-handling data, relying on spreadsheets, or chasing updates between systems, it’s time to change that.

Smart integration and operational gains

We work with manufacturers, wholesalers, and distributors that often don’t have large digital teams. These businesses have big ambitions, but limited capacity holds them back. That’s where integration proves its value.

A fully functioning integration:

- Keeps business systems in sync in real time

- Eliminates manual tasks and admin-heavy processes

- Gives teams the freedom to focus on higher-value work

When it’s set up properly, Orderwise becomes more than just a system of record. It powers your operations in real time and keeps the whole business moving.

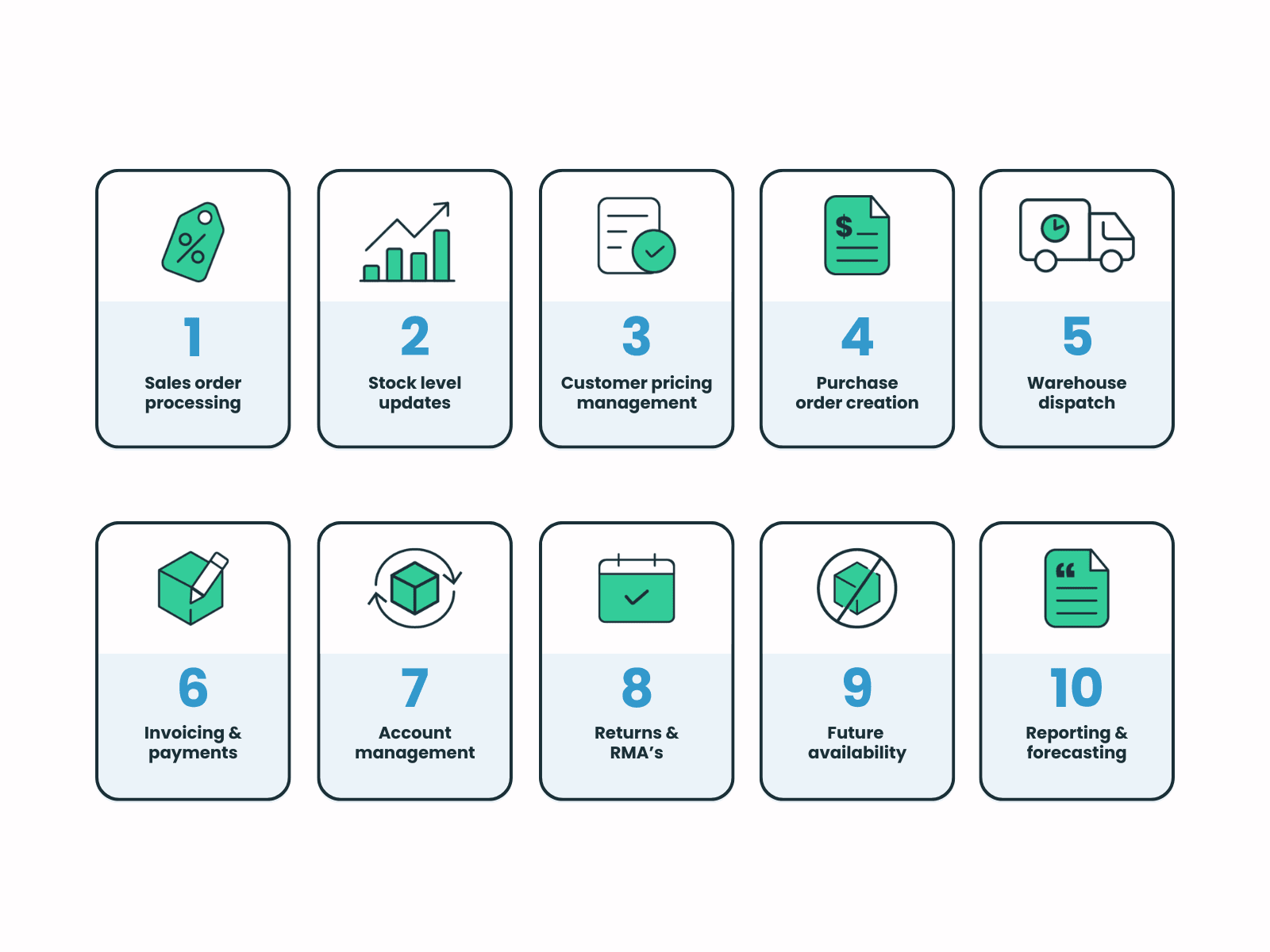

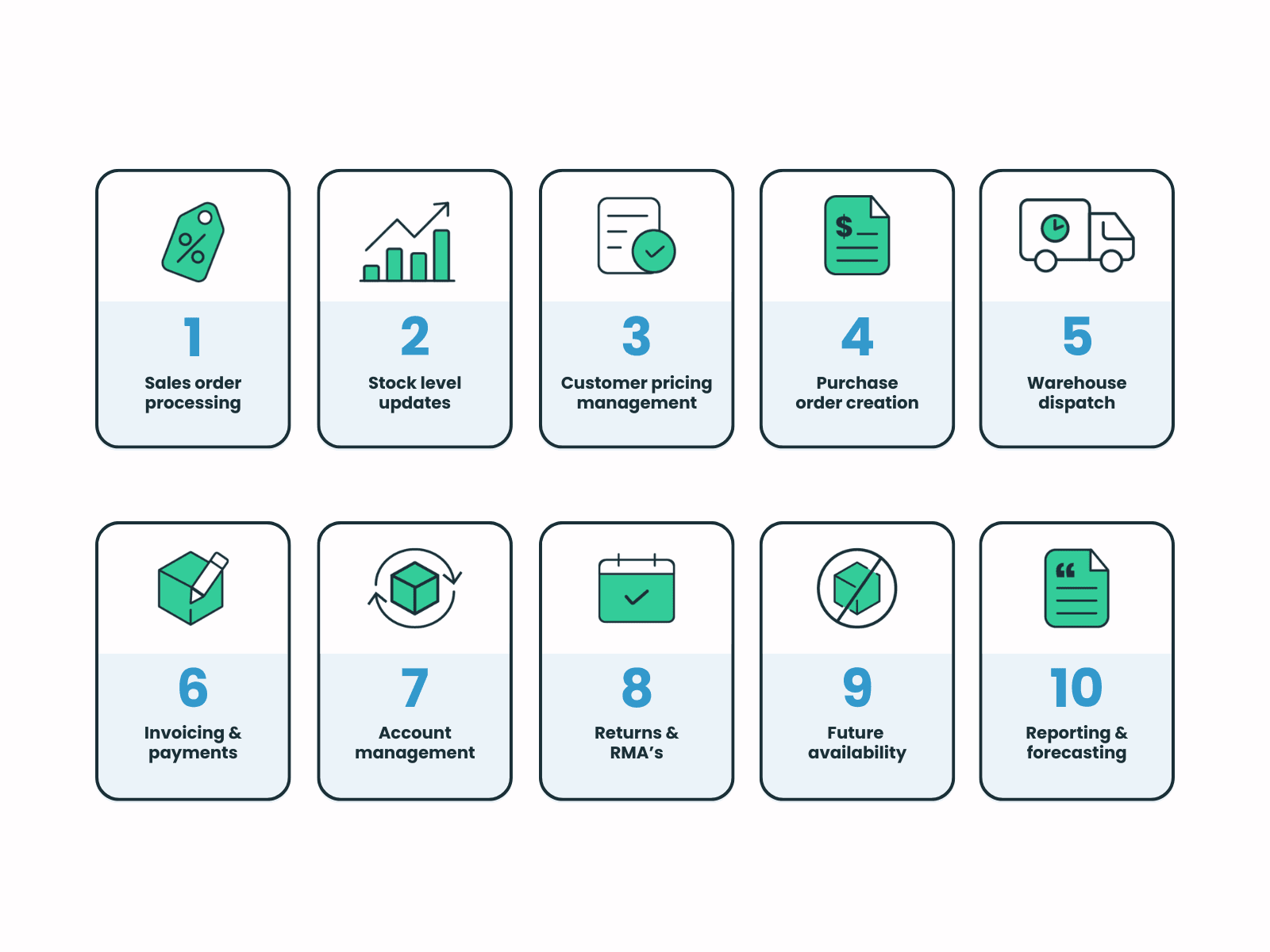

10 business processes that benefit from automation

1. Sales order processing

Manual: Teams re-key orders from the eCommerce platform into Orderwise, risking delays and errors.

Automated: Orders appear instantly in Orderwise, triggering confirmations, fulfilment, and updates.

2. Stock level updates

Manual: Stock data lags between systems, leading to overselling or stockouts.

Automated: All channels reflect live stock status from Orderwise. Even high-frequency changes.

3. Customer pricing management

Manual: Price lists must be manually maintained in multiple places.

Automated: Customer-specific pricing is pulled directly from Orderwise and displayed online.

4. Purchase order creation

Manual: Stock replenishment is handled reactively, often based on outdated reports or guesswork.

Automated: Orderwise uses real-time inventory and sales data to generate purchase orders when stock reaches predefined thresholds automatically.

5. Warehouse dispatch

Manual: Fulfilment teams rely on printed pick lists or delayed handovers.

Automated: Orders flow directly to dispatch teams, keeping fulfilment fast and error-free.

6. Invoicing and payments

Manual: Invoices are manually generated and payment statuses aren’t updated centrally.

Automated: Orderwise handles invoicing and syncs payment data with finance tools or portals.

7. Customer account management

Manual: Teams manually check credit limits, balances, and order histories.

Automated: Self-serve portals show live account data directly from Orderwise.

8. Returns and RMAs

Manual: Return requests are tracked in email threads or spreadsheets.

Automated: Orderwise manages returns end-to-end, with automated updates and tracking.

9. Future availability

Future availability shows customers when products that are currently out of stock will next be available, whether from incoming supplier deliveries or assembly build schedules.

Manual: Teams manually update expected delivery dates or inbound stock figures across systems, often leading to errors or outdated information.

Automated: Orderwise automatically shares inbound stock and build availability online, giving customers clear visibility of when products will be back in stock and increasing confidence to place orders.

10. Reporting and forecasting

Manual: Reporting involves CSV exports and out-of-date snapshots.

Automated: Dashboards and reports update in real time, improving decision-making.

Internal vs customer-facing integration

While front-end features like personalised pricing, live inventory, and delivery tracking enhance the customer experience, they’re only part of the equation.

The real operational gains come from behind the scenes, where internal integrations automate admin-heavy processes, such as order management, stock synchronisation, invoicing, and reporting.

Customer-facing tools win sales; internal automation builds scalable operations.

Only internal integrations reduce headcount pressure, improve data accuracy, and allow your business to grow without increasing overheads. If you’re aiming for both (and you should), don’t stop at surface-level integrations. There’s far more value under the hood, especially when systems like ERP, CRM, and eCommerce platforms are correctly connected.

We build integrations that scale with you

At Rixxo, we uncover inefficiencies, map your existing workflows, and automate the processes that matter most. Whether it’s replacing spreadsheets, reducing order errors, or getting real-time insight into your stock position, we help you build a system that works harder for you.

Because the end goal isn’t integration, it’s what comes after.

Want to know what to automate first?

If you’re not sure where to start, try this:

- Are you rekeying data manually between systems?

- Are you double-checking stock levels before dispatch?

- Are credit limits, balances or returns handled outside Orderwise?

If you answered “yes” to any of these, your business is primed for automation.

Get in touch, let’s map out your next steps.